Direct Effect-Type diaphragm Spring Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

Direct effect-type diaphragm spring reducing valves

Structural feature and function

Y42X type direct effect spring diaphragm reducing valve consists mainly of regulating spring, diaphragm, piston, seat and disc parts etc. Using the diaphragm direct sensing downstream pressure drive disc, control valve disc opening to realize pressure-reducing-and-maintaining function. This product in the urban construction, heat supply system of high-rise buildings, can replace conventional division conduit, saving equipments. It also can usually be in the hot and cold water pipe net, realize pressure reducing-and-stabilizing. This product pressure regulator, smooth movement, suitable for water and the noncorrosive liquid medium pipeline.

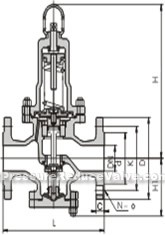

Dimensions & constructral diagram

Direct effect-type diaphragm spring reducing valve constructral diagram

Material of main parts

| Y42X name of parts | MATERIAL OF PARTS |

| body,bonnet,bottom CAP | WCB |

| seat | 2Cr13 |

| disc | 2Cr13 |

| valve rod | 2Cr13 |

| piston | 2Cr13 |

| cylinder sleeve | 2Cr13/25(hard chrome plating) |

| sealing ring | NBR |

| O-shaped ring | NBR |

| adjust spring | 60Si2Mn |

| diaphragm | KNITTING NBR |

Main technical parameter and performance norm

| Y42X nominal pressure (Mpa) | 1.0 | 1.6 | 2.5 |

| casing test pressure(Mpa)* | 1.5 | 2.4 | 3.75 |

| sealing test pressure (Mpa) | 1.0 | 1.6 | 2.5 |

| Max. inlet pressure (Mpa) | 1.0 | 1.6 | 2.5 |

| outlet pressure range(Mpa) | 0.2-0.8 | 0.2-1.0 | 0.4-1.6 |

| flow performance deviation(Mpa)P2G | GB12244-1989 | ||

| pressure performance deviation (Mpa)△P2P | GB12244-1989 | ||

| working temperature | 0℃-80℃ | ||

| leakage quantity | 0 | ||

| *: casing test does not include diaphragm,bonnet | |||

flow factor(Cv)

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Cv | 2 | 3.5 | 4 | 4.5 | 14 | 14.5 | 15 | 60 | 64 | 120 | 140 | 230 | 350 | 520 | 690 | 950 | 1400 |

main connecting dimensions

| Y42X pressure diameter DN | dimensions | ||

| L | H | Hl | |

| 15 | 160 | 225 | 90 |

| 20 | 160 | 265 | 98 |

| 25 | 180 | 265 | 110 |

| 32 | 200 | 265 | 110 |

| 40 | 220 | 320 | 125 |

| 50 | 250 | 320 | 125 |

| 65 | 280 | 325 | 130 |

| 80 | 310 | 385 | 160 |

| 100 | 350 | 385 | 170 |

| 125 | 400 | 430 | 200 |

| 150 | 450 | 430 | 210 |

| 200 | 500 | 560 | 240 |

| 250 | 650 | 690 | 290 |

| 300 | 800 | 800 | 335 |

| 350 | 850 | 880 | 375 |

| 400 | 900 | 980 | 405 |

| 450 | 900 | 1100 | 455 |

| 500 | 950 | 1130 | 465 |

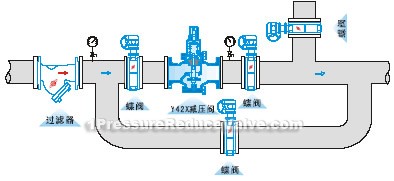

installation scheme