Electric Double Seat Steam Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

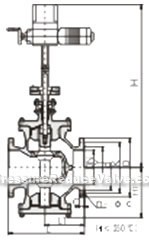

product drawing

Electric double seat steam reducing valves

Structural features and usages

Y945H / Y electric double seat steam reducing valve consists of the body, seat, disc and other parts, adopting double-seat, dual-cone disc structure. Using pressure balance disc, through the disc lift regulating pressure can be equipped with ZKZ-BC type or other type straight stroke electric actuator to achieve remote control and automatic control.

The decompression ratio of this series products are used in 0.6 is more suitable.

This product is mainly used for steam pipes, adjusting the pressure. And it is widely used in combined heat and power, textile, printing and dyeing, petrochemical, sugar refining and other industries.

Dimensions & constructral diagram

Electric double seat steam reducing valve constructral diagram

Main technical parameters and performance index

| nominal diameter | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | |||

| matched actuator type | ZKZ-310BC | ZKZ-410BC/ZKZ-510BC | ZKZ-510BC | ZKZ-610BC/ B+Z250/F1800 | |||||||||||

| stroke | 25 | 30 | 50/30 | 50 | 60 | 100 | |||||||||

| thrust(N) | 4000 | 6400/1600 | 16000 | 2500 | |||||||||||

| all stroke time(S) | 20 | 32 | 37 | 62 | |||||||||||

| input signal | 4-20mA DC | ||||||||||||||

| power supply | 220V 50Hz | 380V 50Hz | |||||||||||||

| basic error(%) | ≤±2.5 | ||||||||||||||

| basic error (%) | ≤±1.5 | ||||||||||||||

| basic error (%) | ≤3 | ||||||||||||||

| nominal pressure(Mpa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

| shell test pressure(Mpa) | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24 |

| sealing test pressure(Mpa) | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 17.6 |

| maximum input pressure(Mpa) | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

| output pressure scope(Mpa) | best pressure reducing ratio0.6 | |||||

| leakage | 0.5%QMax | |||||

| temperature-pressure level | ANSI B16.34 | |||||

The materials of main parts

| part name | part material |

| Body,bonnet,bottom cap | WCB |

| seat | 304 |

| disc | 2Cr13 |

| stem | 2Cr13 |

| gasket | flexible graphite/1Cr18Ni9 |

| guide sleeve | 2Cr13 |

| packing | flexible graphite |

| bolt | 35CrMoA |

| nut | 45 |

(Cv) flow coefficient

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Cv | 15 | 20 | 35 | 60 | 70 | 110 | 150 | 230 | 420 | 540 | 710 | 1020 |

(PN1.6-4.0) external dimensions

| nominal diameter DN | external dimensions | |||

| L | L1 | H | Hl | |

| 50 | 300 | 150 | 880 | 190 |

| 65 | 340 | 170 | 890 | 205 |

| 80 | 380 | 190 | 910 | 215 |

| 100 | 400 | 215 | 950 | 240 |

| 125 | 430 | 225 | 990 | 275 |

| 150 | 450 | 230 | 1090 | 320 |

| 200 | 500 | 260 | 1160 | 340 |

| 250 | 550 | 285 | 1230 | |

(PN6.4-16.0) external dimensions

| nominal diameter DN | external dimensions | |||

| L | L1 | H | Hl | |

| 50 | 300 | 150 | 880 | 200 |

| 65 | 340 | 170 | 890 | 215 |

| 80 | 380 | 190 | 910 | 225 |

| 100 | 400 | 215 | 950 | 250 |

| 125 | 430 | 225 | 990 | 285 |

| 150 | 450 | 230 | 1090 | 330 |

| 200 | 500 | 260 | 1160 | 355 |

| 250 | 550 | 285 | 1230 | 390 |

| 300 | 750 | 395 | 1370 | 480 |

| 350 | 850 | 445 | 1450 | 550 |

| 400 | 950 | 550 | 1570 | 700 |

| 500 | 1130 | 680 | 1780 | 820 |