diaphragm-Type Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

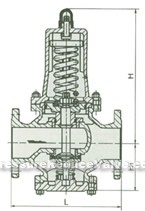

product drawing

diaphragm-type reducing valves

Structrure and function

Y42XSD diaphragm reducing valve series production have reached the international advanced level by introducing new technology and manufacturing process and the structure improvement. The valve is mainly constituted by valve body ,bonnet,compression spring, stem, piston, cylinder sleeve, seat and sealing gasket etc. Its main characteristics: back valve pressure directly impact on the piston below and keep best balance with the pressure above the piston. Action is sensitive, fast, reliable performance and long service life. diaphragm reducing valve applies to working temperature 0 ~ 90 degrees of water, air and hot-cold water supply system and fire fighting water system of the non-corrosive fluids piping and high-rise building. It can replace conventional division pipe, simplified and save system equipment and cut down engineering cost. Changing the material, the temperature can achieve 250 ° c.

Dimensions & constructral diagram

diaphragm-type reducing valve constructral diagram

Main technical parameter

| nominal pressure | inlet pressure | test pressure | outlet pressure P2(MPa) | static and dynamic pressure difference (MPa) | outlet pressure deviation value | |

| PN(MPa) | P1(MPa) | PS(MPa) | DN≤50 | DN≥65 | ||

| 1.0 | ≤1.0 | 1.5 | 0.1∽0.8 | 0.1∽0.8 | 0.06 | ±5% |

| 1.6 | ≤1.6 | 2.4 | 0.1∽1.0 | 0.2∽1.2 | 0.10 | ±10% |

| 2.5 | ≤2.5 | 3.75 | 0.15∽1.6 | 0.25∽1.6 | 0.15 | |

| 4.0 | ≤4.0 | 6.0 | 0.2∽2.5 | 0.3∽2.5 | 0.25 | ±15% |

| 6.4 | ≤6.4 | 9.6 | 0.3∽4.0 | 0.4∽4.0 | 0.40 | ±20% |

| 10.0 | ≤10.0 | 15.0 | 0.45∽6.0 | 0.6∽6.2 | 0.65 | ±30% |

Material of main parts

| name of part | Material |

| body,bonnet,lower cover | Grey Cast Iron, CarbonSteel |

| piston,cylinder sleeve, valve rod | Stainless Steel |

| compressed spring | Si-Mn Steel |

| sealing gasket | NBR |

Main external dimensions

| nominal diameter DN(mm) | L(mm) | H(mm) | H1(mm) | |

| PN10、16、25 | PN40、64、100 | PN10∽64、100 | PN10∽64、100 | |

| 20 | 160 | 180 | 170 | 75 |

| 25 | 180 | 200 | 185 | 80 |

| 32 | 200 | 220 | 195 | 85 |

| 40 | 220 | 240 | 230 | 100 |

| 50 | 250 | 270 | 270 | 115 |

| 65 | 280 | 300 | 310 | 135 |

| 80 | 310 | 330 | 358 | 145 |

| 100 | 350 | 380 | 400 | 165 |

| 125 | 400 | 450 | 430 | 190 |

| 150 | 450 | 500 | 470 | 210 |

| 200 | 550 | 550 | 530 | 245 |

| 250 | 600 | 650 | 616 | 274 |

| 300 | 750 | 800 | 702 | 314 |

| 350 | 800 | 850 | 790 | 355 |

| 400 | 900 | 900 | 883 | 395 |

| 500 | 1075 | 1075 | 995 | 430 |

| 600 | 1295 | 1295 | 1150 | 515 |