The reducing valve regulating principles in the pipeline

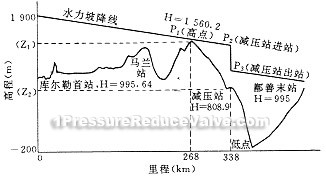

Ku-Shan Pipeline uses two reducing valves, installed in parallel Jueluotage decompression stations, of which the main valve pv1001 play a major regulatory role, the assistant valve pv1002 affacts as set aside and regulating, Ku-Shan oil pipeline project hydraulic gradient line diagram shown in Figure 4.

Figure 4 Ku-Shan oil pipeline first diagram project hydraulic gradient line

From Figure 4 you can see the main effect of the valve.

(1) In decompression station through reducing valve throttling to decompress, consumes the highest point of pipe to the end that between them excess potential energy (p2-p3).

(2) Through reducing valve controlling decompression station upstream pipeline pressure, to ensure that high pressure operation, and avoid the pipeline of high point to decompression station happens non-full flow phenomenon.

(3) When the full range is decommissioning, through reducing valve tightly closing, preventing decompression station upstream happens blank pipe phenomenon that goes against re-start.

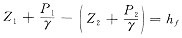

Figure 4, the high point and the decompression station with simplified Bernoulli equation of steady flow energy equation〔2〕

ie p2=p1+γ(z1-z2)-γ.hf

from the Repin Formula were:

(1)

in formula z1——high point and altitude,m;

z2——decompression station altitude,m;

p1——high piont pressure,pa;

p2——decompression station entering pressure,pa;

q——original oil flow in pipes,m3/s;

d——pipe inner diameter,m;

l——the pipe length between high point to decompression station,m;

γ——oil relative density,kg/m3;

ν——oil moving viscosity,m2/s;

β——flow coefficient,take 0.0246 s2/m。

Where z1, z2, d, l, β, γ, ν are known, in order to ensure the high pressure operation, take p1 as 0.2 mpa (design reference value), from equation (1) can be drawn: decompression stops entering pressure p2 changes by q changes, q take the first stop outbound flow. In the actual operation, psp (decompression stops entering pressure set value) is calculated by the scada system based on real-time measurement of q, and from the host system to transmit real-time decompression station control plc, from the pid regulating program (proportional integral derivative) within the plc to control the upstream pressure p2 of decompression stops.

when p2<psp,pv1001 closes small,until deviatione=p2-psp=0;

when p2>psp,pv1001opens big,until deviatione=0为止;

when p2=psp,pv1001 keeps the present opening degree.

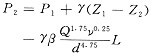

Vice-valve pv1002 is a stand-regulating valve, its pressure setting value is a fixed value, that is, not change with the pipe flow rate varies. When the main valve pv1001 closes due to failure or lack of circulation capacity, the vice valve will automatically be involved in the regulation, the two valves pressure flow curves are shown in Figure 5.

Figure 5, pressure flow curves

As can be seen from Figure 5, the main valve pv1001 control upstream pressure decreases with the flow rate increases, while the Vice-valve pv1002 control upstream pressure is a certain value, the two valve outlet pressure (change by flow rate) is the same.