Selection

Reducing valve inlet pressure fluctuations should be controlled at 80% ~ 105% of the given inlet pressure value, if exceeding this range, reducing valve performance will be affected.

1. usually the reducing valve pressure P2 after valve should be less than 0.5 times of pressure before valve, namely P2 <0.5P1.

2. Reducing valve each spring is only applied in the context of a certain outlet pressure, beyond the scope should replace springs.

3. In the relatively high media operating temperature occasion, generally selecting pilot-piston reducing valve or pilot bellows-type reducing valve.

4. Medium is air or water (liquid) occasion, generally should choose direct-acting diaphragm reducing valve, or pilot-type diaphragm reducing valve.

5. Medium is steam occasions, should use the pilot piston reducing valve or pilot piston bellows reducing valve.

6. In order to operate, adjust and maintain convenience, the reducing valve should normally be installed on the level pipeline.

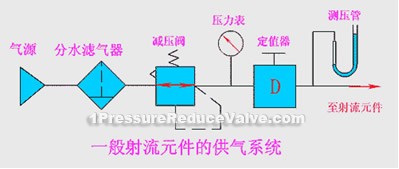

according to using requirements to select reducing valve type and pressure regulating precision, then according to the required maximum output flow rate to choose their diameter. When determining gas source pressure, should make it more than the maximum output pressure 0.1MPa. Reducing valves are usually installed after air filtration devices, before the oil mist device or valuation device, and be careful not to connect contrary of its inlet and outlet; you should relax the knob when the valve is not used, to avoid diaphragm compression to affect its performance.