Various reducing valve working principles

direct-acting reducing valve

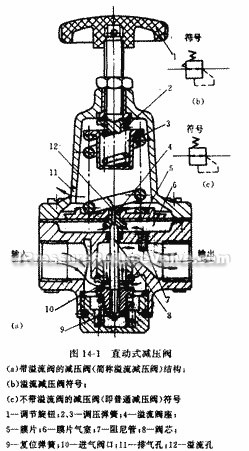

Figure 14-1a shows the direct-acting pressure reducing valve with relief valve (referred to overflow reducing valve) structural diagram

Compressed air of P1 pressure, from the left end input and after valve port 10 throttling, the pressure reduced to P2 output. The size of P2 can be adjusted by regulative springs 2,3. twisting knob 1 clockwisely, compressed springs 2,3 and diaphragm 5 makes core 8 down, increasing valve port 10 opening degree to increase P2. If the counter-clockwise rotating knob 1, the opening degree of valve port 10 decreases, P2 decreases.

If P1 instantaneous rises, P2 will subsequently increase, makes diaphragm chamber 6 pressure increases, thrust is corresponding increase on diaphragm 5, the thrust destroys the original force balance, makes diaphragm 5 moving upwards, a small part of the air flow exhaust out through the overflow hole 12, exhaust hole 11. In the diaphragm moving upwards, because the reset spring 9 effect, so that core 8 is also moving up, closing intake air valve port 10, throttling function increases, makes the output pressure drops until it reaches a new balance, the output pressure back to the original value fundamentally. If the input pressure transient drop, so does the output pressure, diaphragm 5 moves down, core 8 followed down, intake valve port 10 opens large, throttling function reduces, makes the output pressure is basically back to the original value. Counterclockwise rotating knob 1. makes regulative spring 2,3 relax, thrust of gas acting on the diaphragm 5 is greater than the regulating pressure spring force, diaphragm bends upward, by reset spring effect to close intake valve port 10. And then rotating knob 1, the top of the intake valve core 8 and the relief valve seat 4 would be torn off and the compressed air of the diaphragm air chamber 6 will be through the overflow hole 12, exhaust hole 11 to exhauxt out, so that valve is in the non-output state.

In short, the overflow valve is by the inlet throttling for decompression, and stablize pressure according to balance function of diaphragm upper piece and overflow function of overflow hole; adjusting the springs will make the output pressure changing within a certain range. In order to prevent the aboved overflow reducing valve exhausting out a small amount of gas that will pollute the surrounding environment, you can use reducing valve without overflow valve (ie, normal pressure reducing valve), its symbol as shown in Figure 14-1c.

pilot reducing valve

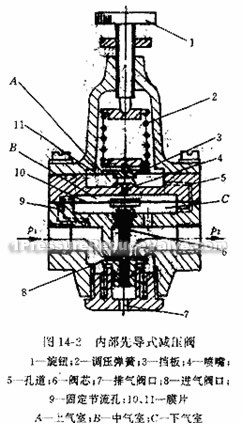

When the valve's output pressure is higher or diameter is larger, using pressure regulating spring direct regulates pressure, then spring stiffness must be too large, flow rate changes, the output pressure fluctuation is larger, the valve structure and size will increase. In order to overcome these shortcomings, pilot-type valve can be used. Pilot-valve working principles are basically the same with the direct-acting type. Pilot pressure regulating valve used gas is supplied by small direct-acting pressure reducing valve. If installing the small direct-acting pressure reducing valve on the internal body, then known as the internal pilot type valve; if installing it on the external main body, then known as the external pilot type valve . Figure 14-2 shows the structure diagram of the internal pilot type reducing valve, compared with the direct-acting pressure reducing valve, the valve increases by nozzle 4, baffle 3, the fixed throttle hole 9 and the gas chamber B formed baffle larger part of the nozzle. When the distance between the nozzle and baffle occurs small changes, they will make B pressure significant changes, causing diaphragm 10 has a larger displacement, to control the spool 6 moves up and down, makes inlet 8 to open large or off small, increase the sensitivity of the spool control, namely, increase stablizing pressure accuracy.

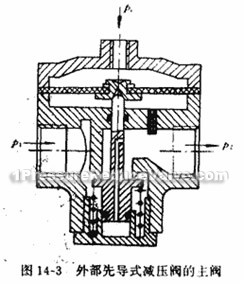

Figure 14-3 shows the main valve of the external pilot type valve, its working principles are the same with the direct-acting type. Outside the main body there is a small direct-acting pressure reducing valve (do not show in the figure), by which to control the main valve. Such valve is suitable for diameter 20mm or more, distance (30m or less), height, danger part, the difficult regulating occasions.

Valuation device

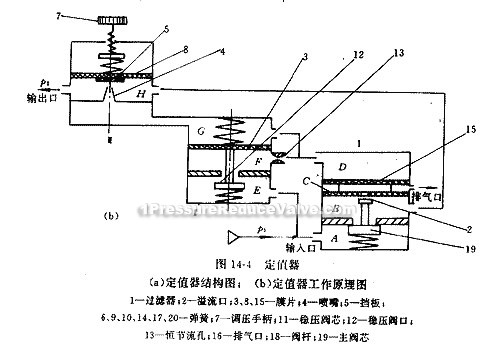

Valuation device is a high-precision pressure reducing valve, mainly for the pressure setting value. There are two kinds of pressure specified valuation device: its air supply pressure is respectively 0.14MPa and 0.35MPa, the output pressure range is respectively 0-0.1MPa and 0-0.25MPa. its output pressure fluctuation is less than 1% of maximum output pressure, often used in requiring the supply of precision air source pressure and signal pressure occasion, such as pneumatic laboratory equipment, pneumatic automatic devices.

Figure 14-4 shows the valuation device working principle diagram. It consists of three components: 1. main closed part of direct-acting pressure reducing valve; 2 is a constant pressure drop device, representing a certain decline pressure reducing valve. the main function is ensure a stable gas supply flow for nozzle; 3 is a nozzle baffle device and pressure regulating parts, affect as regulating and pressure amplification, using the enlarged air pressure to control main valve part.

As the valuation device has a set, compare and zoom functions, thus with high stablizing pressure precision.

Valuation device is in a non-working state, the compressed air input by gas source after filtered through the filter 1 and enters into room A, and positive room. The main spool 19 presses on the seat under the spring 20 and gas source pressure effect, disconnecting A and B room. The air flow enters into the chamber through the valve port (also known as the living port) 12 to F room, and through constant throllting hole 13 to reduce pressure, respectively entering into G room and D room. As the time has not yet added force to diaphragm 8, the space between baffles 5 and nozzle 4 is larger, the airflow resistance of gas flow from nozzle 4 is smaller, G room & D room air pressure is lower, diaphragm 3 and 15 maintain its original location. The entered gases mainly exhaust by the exhaust port through valve port 2; another exhaust out from outlet. At this point the output port is no airflow output, discharge from the nozzle and empty trace gases is the required worl to maintain nozzle baffle installation, because it is the non-reactive gas consumption, so the smaller its consumption, the better.

when valuation device is in working condition, turning the handle 7 and pushed down spring 6 and promote the diaphragm 8, together with the baffle 5 downward movement, the distance between baffle 5 and the nozzle 4 narrows, flow resistance increases, makes G room and D room pressure rise. diaphragm 16 move down under D room air pressure effect, it will close the valve port 2 and promote main spool 19 to open the valve port, the compressed air through room B, and H room from the output port to output. At the same time, H chamber pressure rises and feeds back to the diaphragm 8, when the diaphragm 8 and the spring force suffered feedback force is balance, valuation device will output certain pressure gases. When the input pressure fluctuates, such as pressure increases, B room and H chamber pressure transient increase, makes diaphragm 8 moving upward, leading to the spacing between baffle 5 and nozzle 4 increased, G room and D room pressure drops. Since B room pressure increases, D chamber pressure drops, diaphragm 15 moves upward under the effect of pressure differential, makes main valve port decreases, the output pressure drops, until the stability to the set pressure. In addition, when the input pressure rises, E and F Room instantaneous pressure also rise and diaphragm 3 moves up under the effect of up and down pressure differential, closing small regulator valve port 12. because of throllting strengthened, F room air pressure drops, and always maintain the pressure differential constant before and after the orifice 13, and therefore the gas flow through the orifice 13 remains unchanged, makes the nozzle baffle sensitivity improved. When the input pressure is lowered, B rooms and H room transient pressure declines, diaphragm 8 together with baffle 5 damage due to force balance and move downward, the sapce between the nozzle 4 and baffle 5 decreases, G room and D chamber pressure rise, diaphragm 3 and 15 move down. diaphragm 15 moves down to increase main valve port opening, makes B and H chamber pressure risen, until it is balance with set pressure. The diaphragm 3 moves down, makes stablize pressure port 12 opened, F chamber pressure rises, and always maintain pressure constant before and after the constant orifice 13. Similarly, when the output pressure fluctuates, it will be the same adjustment with the input pressure fluctuations.

As the valuation device uses the output pressure feedback and nozzle baffle amplification to control main valve so that it can respond to small pressure changes, and the output pressure can be adjusted on time, maintain the basic stability of outlet pressure, namely, valuation regulators accuracy is higher.