Y41X Adjustable Pressure Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

Y41X Adjustable Pressure Reducing Valve

Overview

The Y41X Adjustable Pressure Reducing Valve is a precision hydraulic control valve integrating pilot control and main valve linkage, specifically designed for medium and high-pressure pipeline systems requiring extremely high pressure stability. It senses and amplifies the downstream pressure signal through the pilot valve, and precisely drives the main valve disc to act hydraulically. This automatically and smoothly reduces the high, unstable inlet pressure to the user-preset outlet pressure value and locks it in. Its core function is to achieve precise pressure stabilization under conditions of large flow and high pressure difference, effectively eliminating pipeline network pressure fluctuations and protecting the safety of downstream equipment. Adopting flange connection, the valve is usually made of ductile iron or stainless steel as the main material. It is widely used in the main pipelines of high-rise building water supply, district water supply networks, fire protection systems, industrial circulating water and large-scale irrigation systems, serving as the core equipment for system pressure zoning and control.

Features

1.Pilot Control, Precise Pressure Stabilization Adopts a hydraulic linkage structure with separate pilot valve and main valve. Acting as an "intelligent controller," the pilot valve highly sensitively senses downstream pressure changes and drives the main valve piston or diaphragm through the control pipeline, enabling large-stroke, smooth opening and closing of the main valve disc. This design provides strong compensation capability for inlet pressure fluctuations and flow changes, delivering high outlet pressure control precision—far superior stability compared to direct-acting pressure reducing valves.

2. Wide Adjustable Range, Strong Adaptability Equipped with a wide-range, high-precision pressure adjustment mechanism. Within the valve’s rated operating range, users can continuously and linearly set the required outlet pressure by adjusting the adjusting screw on the pilot valve. The wide adjustment range meets various pressure demands of different zones or equipment, ensuring broad adaptability.

3. Flange Connection, Abundant Flow Capacity Features standard flange connection (e.g., PN16/PN25) with a large diameter range (commonly DN50 and above). The optimized flow channel design minimizes fluid resistance, meeting the high-flow requirements of main pipelines while maintaining stable pressure reduction. It boasts low pressure drop loss and significant energy-saving effects.

4. Self-Cleaning Design, Reliable Operation The main valve disc typically adopts a piston-like structure, which achieves self-cleaning during opening and closing to effectively prevent impurity deposition and jamming. The pilot control circuit is usually equipped with a built-in filter screen to protect the precision pilot valve from pipeline impurities, ensuring long-term reliable and maintenance-free operation even in complex water quality conditions.

5. Multi-Functional, High Integration In addition to the core pressure reducing and stabilizing functions, it usually integrates pressure relief and retention capabilities. When the downstream pressure abnormally rises beyond the safe set value, the valve automatically opens to relieve pressure; it can also be adjusted to pressure retention mode when maintaining the minimum pipeline pressure is required. Some models offer optional pressure gauge interfaces for intuitive pressure monitoring, achieving high functional integration.

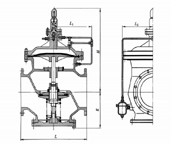

Dimensions & constructral diagram

Y41X Adjustable Pressure Reducing Valve constructral diagram

1、Pressure gaugege2、Pilot Valve3、Filter4、Flow regulating valve 5、Main Valve

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Valve body | Cast iron, cast steel WCB, CS |

| 2 | Valve bonnet | Cast iron, cast steel WCB, CS |

| 3 | Chromium-manganese disc spring | Chromium-manganese steel |

| 4 | Regulating spring | Silicon-manganese steel |

| 5 | Stainless steel diaphragm | Stainless Steel |

| 6 | Piston ring | Alloy wear-resistant cast iron |

Main technical parameter

| Performance Specification | |

|---|---|

| Nominal Pressure | 1.6 MPa |

| Shell Test | 2.4 MPa |

| Seal Test | 1.76 MPa |

| Suitable Temp. | ≤80 ℃ |

Specification and dimensions

| Model | Dimensions | Nominal Diameter DN | ||||||

|---|---|---|---|---|---|---|---|---|

| 125 | 150 | 200 | 250 | 300 | 350 | 400 | ||

| Y41X-16 Y41X-16C |

L | 400 | 450 | 500 | 600 | 750 | 800 | 800 |

| L | 250 | 270 | 300 | 350 | 435 | 460 | 460 | |

| L₂ | 270 | 290 | 320 | 370 | 455 | 480 | 480 | |

| E | 180 | 180 | 225 | 250 | 349 | — | — | |

| H | 415 | 415 | 475 | 510 | 820 | 950 | 1050 | |