YZ11X Stainless Steel Branch Pipe Pressure Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

YZ11X Stainless Steel Branch Pipe Pressure Reducing Valve

Overview

The YZ11X stainless steel branch pipe pressure reducing valve is a compact direct-acting pressure reducing device specifically designed for pipeline branch systems. Adopting a spring-diaphragm mechanical linkage structure, it achieves automatic pressure stabilization through the dynamic balance between medium pressure and spring force. The valve can stably reduce the high and unstable pressure of the main pipeline to the set working pressure required by branch pipes or terminal equipment, effectively preventing water hammer, overpressure and pressure fluctuations from damaging the branch system. Its integral stainless steel structure balances corrosion resistance and structural strength, making it an ideal choice for precise regional pressure control in building water supply, HVAC systems, industrial equipment branch pipelines and clean fluid systems. The valve features internal thread or crimping connections with a sophisticated and compact structure, suitable for installation in space-constrained pipeline branches, equipment inlets and instrument front ends—especially for application scenarios with high requirements for hygiene level and corrosion resistance.

Features

1. Compact Design for Branch Pipes

The valve body adopts a streamlined integral forging structure, featuring small size and light weight. It can be directly installed at pipeline branches or equipment inlets without additional support. With flexible installation directions, it is suitable for both horizontal and vertical pipelines, greatly saving installation space and simplifying pipeline layout.

2. All-Stainless Steel Corrosion-Resistant Structure

The valve body, bonnet and key internal components are made of 304/316 stainless steel. The surface is precision-polished or passivated, offering excellent corrosion resistance and erosion resistance. It is fully applicable to hygienic working conditions such as drinking water, high-purity media, weakly corrosive chemical fluids and high-temperature hot water.

3. Direct-Acting Sensitive Pressure Stabilization

Equipped with a pressure sensing system composed of a high-elasticity stainless steel diaphragm and a precision adjusting spring, it responds sensitively to downstream pressure changes and can instantly drive the valve core for compensation adjustment. No external control source is required, and it can maintain stable outlet pressure when flow changes, with a control accuracy of ±10%.

4. Built-In Filtration and Anti-Clogging Design

The water inlet end of the valve body integrates a high-mesh stainless steel filter screen (usually 80-100 meshes), which effectively intercepts pipeline impurities and prevents particles from jamming the valve core or wearing the sealing surface. The straight flow channel design has no retention dead ends, reducing the risk of impurity accumulation and extending the valve service life.

5. Easy Adjustment and Maintenance

A top-mounted adjusting knob with a dust cover allows intuitive setting of the outlet pressure value (usually adjustment range 0.05-0.8MPa) by rotating with tools. Adopting modular sealing components, replacement of diaphragms or seals can be completed without disassembling the valve body, significantly reducing operation and maintenance costs.

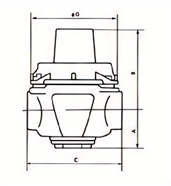

Dimensions & constructral diagram

YZ11X Stainless Steel Branch Pipe Pressure Reducing Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Valve body | stainless steel |

| 2 | Valve disc | stainless steel |

| 3 | O ring | NBR |

| 4 | Seal ring | NBR |

| 5 | Diaphragm | Fabric-Reinforced Nitrile Rubber |

| 6 | Regulating spring | 60Si2Mn |

| 7 | Regulating bolt | 2Cr13 |

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.0/1.6 | MPa |

| Shell Test | 1.5/2.4 | |

| Seal Test | 1.1/1.76 | |

| Suitable Temp. | ≤80 | ℃ |

Specification and dimensions

| Nominal Diameter DN (mm) | Dimensions (mm) | ||||

|---|---|---|---|---|---|

| mm | in | A | B | C | G |

| 15 | 1/2 | 30 | 83 | 87 | 72 |

| 20 | 3/4 | 30 | 83 | 87 | 72 |

| 25 | 1 | 34 | 100 | 88 | 80 |

| 32 | 1 1/4 | 40 | 115 | 102 | 80 |

| 40 | 1 1/2 | 56 | 130 | 122 | 100 |

| 50 | 2 | 56 | 130 | 122 | 100 |