ZZYP Self-Operated Pressure Reducing Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

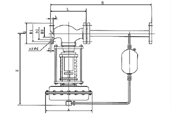

product drawing

ZZYP Self-Operated Pressure Reducing Valve

Overview

The ZZYP self-operated pressure reducing valve is an automatic pressure regulating device driven by the medium's own energy. Adopting the direct-acting pressure sensing and control principle, it can accurately regulate and stably output the pipeline system pressure without external power supply or air source. The valve senses downstream pressure changes through built-in pressure sensing elements (such as diaphragms and bellows) and drives the valve core to automatically adjust the opening degree, thereby stably reducing the high and unstable pressure at the inlet to the set outlet pressure value. Its design emphasizes energy efficiency and reliability, and it is widely used in pressure control occasions without external power or with high explosion-proof requirements, such as steam heating, compressed air, gas supply, and industrial fluids. The valve adopts a cast steel, stainless steel or copper alloy valve body with a compact and robust structure, supporting flange and thread connection methods. It is a key equipment for realizing pressure zoning control of process systems, pressure stabilization at equipment inlets, and safe and energy-saving operation.

Features

1. Self-Operated Drive for Energy Saving and Reliability

It fully utilizes the pipeline medium's own pressure as the driving energy, realizing automatic pressure stabilization without relying on external power supply, air source or complex control systems. This design not only reduces energy consumption and operating costs but also avoids control failure caused by external power faults, ensuring high system reliability.

2. Direct-Acting Sensitive Regulation

Equipped with a force balance system composed of high-sensitivity pressure sensing elements (diaphragm/bellows) and precision springs, it responds quickly and directly to downstream pressure changes. The regulating mechanism has no intermediate transmission links, featuring timely dynamic response and stable pressure control with an accuracy of ±5%~10% of the set value.

3. Compact Structure and Strong Adaptability

Adopting an integrated valve body design, it is small in size and flexible in installation, supporting horizontal or vertical mounting. It is widely applicable to various media such as steam, compressed air, nitrogen, liquefied gas and oil products, with a wide operating temperature range (-20℃~350℃) and pressure resistance grade up to PN16~PN40.

4. Versatile Control with Flexible Configuration

By replacing the actuator type or adjusting the pressure guiding configuration, it can achieve multiple functions including downstream pressure regulation (pressure reducing and stabilizing), upstream pressure regulation (pressure relief and holding) and differential pressure control, meeting different pressure control needs of process systems.

5. Easy Maintenance and Long-Term Stability

The control mechanism adopts a modular design, and main wearing parts (such as diaphragms and sealing rings) can be quickly replaced without disassembling the valve body during maintenance. The overall structure is robust, and key components are treated for corrosion and wear resistance, making it suitable for continuous operation with long service life and low maintenance costs.

Dimensions & constructral diagram

ZZYP Self-Operated Pressure Reducing Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Valve body | ZG230-450, ZG1Cr18Ni9Ti, ZGCr18Ni12Mo2Ti |

| 2 | Stem | 1Cr18Ni9Ti, Cr18Ni12Mo2Ti |

| 3 | Diaphragm cover | A3, A3 Steel Coated with PTFE, stainless steel |

| 4 | Packing | NBR, EPDM, Fluoro Rubber, Oil-Resistant Rubber |

| 5 | Valve Core | 1Cr18Ni9Ti, Cr18Ni12Mo2Ti |

| 6 | Seat | 1Cr18Ni9Ti, Cr18Ni12Mo2Ti |

Performance Specification

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.6/4/6.4 | MPa |

| Shell Test | 2.4/6/9.6 | |

| Seal Test | 1.76/4.7/7.04 | |

| Suitable Temp. | ≤80 | ℃ |

Specification and dimensions