ZZYVP Self-Operated Nitrogen-Sealing Pressure Regulating Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

product drawing

ZZYVP Self-Operated Nitrogen-Sealing Pressure Regulating Valve

Overview

The ZZYVP self-operated nitrogen-sealing pressure regulating valve is a self-operated micro-pressure control device specifically designed for the nitrogen sealing protection system of storage tanks. Adopting the medium self-driven force balance principle, the valve senses pressure changes in the gas phase space at the top of the storage tank through a sensitive diaphragm, automatically adjusting the nitrogen supply or exhaust volume to accurately maintain the internal tank pressure within the set micro-positive pressure range (usually 0.1-5kPa). Its core function is to isolate air through a continuous and stable nitrogen blanket, preventing oxidation, volatilization or moisture absorption of materials in the tank while ensuring the structural safety of the storage tank. It is widely used in the tank protection systems for volatile liquids or sensitive materials in chemical, petroleum, pharmaceutical, food and other industries.

Features

1. Specialized Micro-Pressure Control for Nitrogen Sealing

Designed specifically for the special requirements of tank nitrogen sealing working conditions, it can achieve high-precision control of micro-positive pressure within the range of 0.1-5kPa (sensitivity up to ±50Pa). Equipped with a special low-pressure difference diaphragm and light-load spring set, it ensures operational sensitivity and control stability under micro-gas regulation conditions.

2. Dual-Action Control Mode

Integrates dual functions of nitrogen supply regulation and nitrogen relief control. Automatically opens to supplement nitrogen when the internal tank pressure is lower than the set value, and automatically opens to exhaust when the pressure is higher than the set value, maintaining dynamic pressure balance inside the tank. A single valve achieves bidirectional regulation, simplifying the system structure and reducing installation costs.

3. Corrosion Resistance and Sealing Safety Design

Components in contact with gas inside the valve are made of stainless steel or polytetrafluoroethylene (PTFE), resistant to corrosion from nitrogen and chemical volatile gases. The sealing structure adopts soft-hard composite sealing or metal bellows sealing to achieve long-term zero leakage, preventing external air infiltration or ineffective nitrogen escape.

4. Adaptive Performance and Safety Redundancy

Built-in damping mechanism can suppress pressure sudden change interference caused by material inlet and outlet of the tank. Optional dual-valve combination or overpressure rupture disc is available as safety redundancy to ensure tank pressure safety under extreme working conditions. The pressure tapping port design can be equipped with an isolation tank to prevent medium crystallization or blockage from affecting pressure sensing.

5. Energy-Saving Self-Drive and Intelligent Integration

No external energy source is required; the valve is driven by pressure changes of the tank itself, which is energy-saving and suitable for explosion-proof areas. It can be integrated with pressure transmitters and digital controllers to upgrade into an intelligent nitrogen sealing system, supporting remote monitoring, pressure curve recording and fault early warning, realizing refined energy management and safety control.

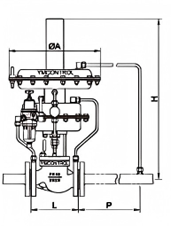

Dimensions & constructral diagram

ZZYVP Self-Operated Nitrogen-Sealing Pressure Regulating Valve constructral diagram

Material of main parts

| NO. | Name | Material |

|---|---|---|

| 1 | Valve body | ZG230-450, ZG1Cr18Ni9 |

| 2 | Valve Trim | 1Cr18Ni9Ti |

| 3 | Diaphragm cover | A3, 1Cr18Ni9Ti |

| 4 | Diaphragm | Rubber Reinforced with Polyester Fabric, Fluoro Rubber |

| 5 | Spring | 60Si2Mn, 1Cr18Ni9Ti |

Performance Specification

| Performance Specification | ||

|---|---|---|

| Nominal Pressure | 1.6 | MPa |

| Shell Test | 2.4 | |

| Seal Test | 1.76 | |

| Suitable Temp. | ≤80 | ℃ |

Specification and dimensions

| DN | L | H | A | P |

|---|---|---|---|---|

| 20 | 184 | 548 | Φ308 | 180 |

| 25 | 184 | 548 | 180 | |

| 32 | 180 | 565 | 220 | |

| 40 | 200 | 565 | 220 | |

| 50 | 230 | 565 | Φ394 | 300 |

| 65 | 290 | 595 | 400 | |

| 80 | 310 | 595 | 400 | |

| 100 | 350 | 595 | 570 |